Working Principle

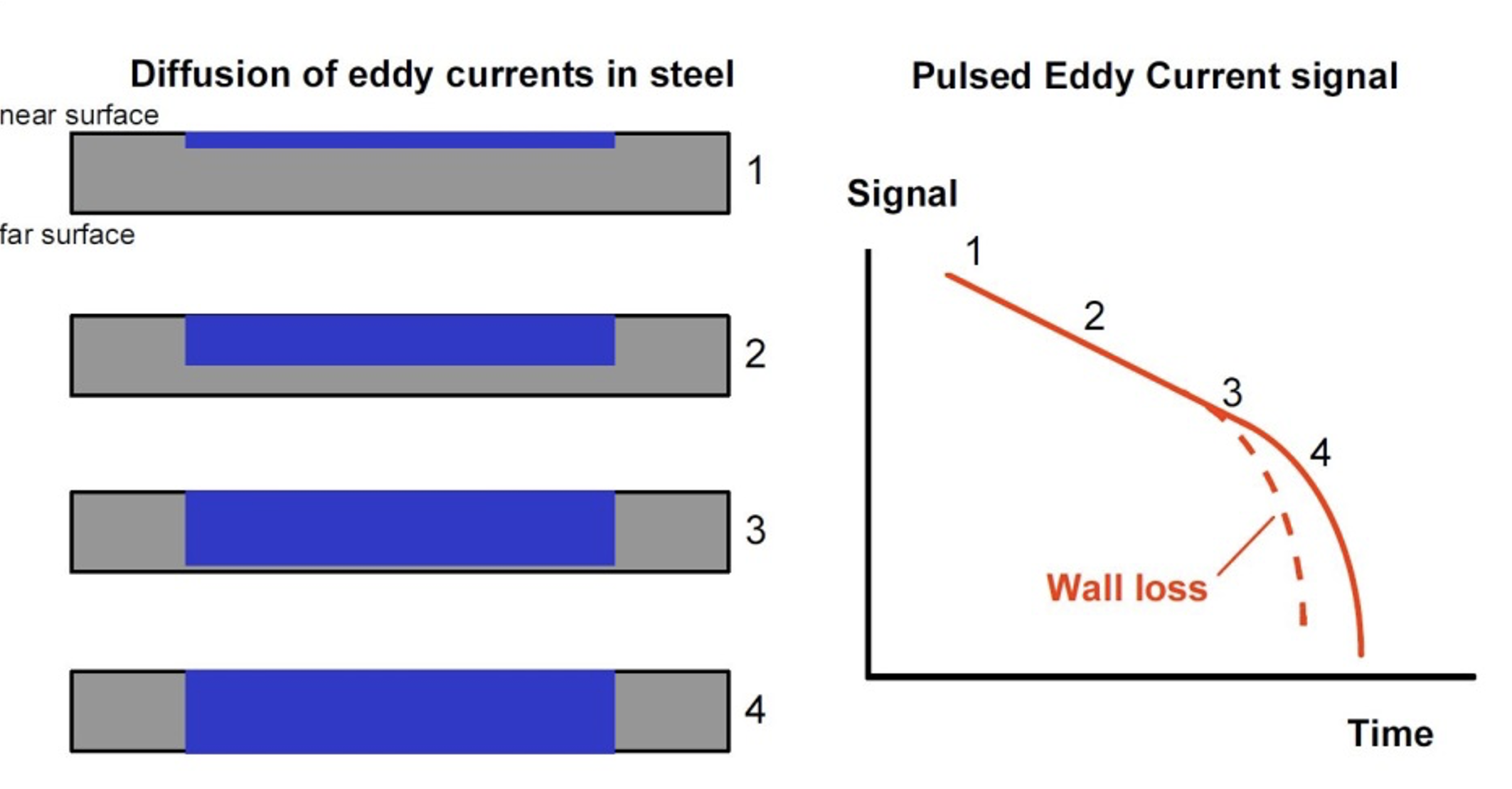

BonPEC is based on Pulsed Eddy Current (PEC). It measures the decay time of the pulsed eddy current induced in the object under examination. This pulsed eddy current is induced in the material by means of a DC current circulating through the sending coil circuitry of the BonPEC probes. This DC current generates a magnetic field that takes a while before getting uniform and stable. The magnetic field lines generated are closed lines and move through the insulation and the ferromagnetic object under examination. At the moment the current is cut off, the sending coil stops generating the magnetic field. During this transient, pulsed eddy current is induced in the ferromagnetic object under examination. This eddy current migrates and decays through the object wall and rapidly extinguish when it reaches the opposite object side. Eddy current is a circulating current and it generates during its decay a variable magnetic field. Its field lines move through the sensor. BonPEC measures the resulting decay of the magnetic field versus time which is a function of the object thickness and of its material electromagnetic properties.

The figure above represents schematically the decay of the induced pulsed eddy current through a carbon steel object wall. The pulsed eddy current measured signal is presented in a double logarithmic graph: the horizontal axis represents the time in milliseconds (ms) and the vertical one the measured signal amplitude (µT). Characteristic of this signal is the presence of a bending point that indicates the induced eddy current decay time.

At this time the eddy current reached the far surface of the object and rapidly disappears (signal drop after bending point). This time is called TAU (τ) and it is a function of the material magnetic permeability (µ), of the material electrical conductivity (σ) and of the square of the object average thickness (d) in the footprint area, and it is given as τ = µσd2 (see figure above).

Reference measurement

BonPEC needs no reference blocks for the examination set up and calibration. The reference block is the object under examination. Before starting the object examination, a reference measurement is needed. The reference measurement will give per definition an average wall thickness (AWT) of 100% and its signal will be compared with all other measurements. The reference measurement shall be taken on a good object part and/or on the thicker location in an area free of appendances and uniform in thickness. When possible, the reference measurement shall not be adjoining cell measurements with a variance larger than 2% of the reference thickness, the edge of a grid, intrados of an elbow or blank cells where obstructions are present. The reference measurement shall not be taken on sheeting overlap or near obstacles.

At the end of the survey, during its evaluation, the reference shall be verified and if a thicker and more uniform area with good signals will be identified, then the reference location will be replaced with the best signal within this area.

Accuracy and reproducibility

The measurement accuracy in normal operating conditions is +/- 5% of the reference value under the condition that the AWT reduction of the measurement is not less than 50% of reference value (100% and thicker area of the object) and that its lift-off variation does not exceed +/- 50% of the reference value lift-off.

The reproducibility of the tool at a single location is about 2% under the same condition of AWT and lift-off variation mentioned above. Field experience in a monitoring situation showed that keeping track of the exact measurement locations is of major importance; as paint can be washed away and the insulation or sheeting material is not necessarily fixed to a location on the pipe.

Screening

BonPEC is a screening tool and a qualitative inspection technique: it gives real time information about the status of the insulated object in order to discriminate the areas of interest on which to perform a deeper survey.

No direct contact and special surface cleaning is required to operate BonPEC. This non-contact characteristic makes it possible to detect corrosion on high temperature surfaces without many probe adaptations. A simple thermal shield protects the probe from extreme temperatures allowing measurements up to +500 ºC. Above this temperature the reduction of the magnetic permeability in the object reduces the reliability of the pulsed eddy current signal.

There is no need to remove insulation or coating, which reduces cost and increases the inspection speed. Coupling the signal to the object is not critical and it allows the technique to be used under uncommon circumstances.

Corrosion and scab

Piping with corrosion scabs

BonPEC is also effective in measurement through corrosion product and scab (figure above). To perform these measurements a dedicated algorithm and an additional lift-off between the probe and the surface of the object under examination has to be applied to reduce their interference. Corrosion products and scab have a magnetic permeability similar to that one of the carbon steel base material of the object under examination but they have a lower electric conductivity. By applying this additional lift-off the pulsed eddy current signal generated in these corrosion products and scabs will get weaker than the response of the pulsed eddy current signal generated in the object based material, allowing the detection of the remnant Average Wall Thickness (AWT).