The Software

The software program designed for BonPEC, facilitates the interpretation of the decay signal for a user defined measurement grid.

The program is based on the way that a typical NDT survey is performed. Initially one needs to know what needs to be investigated, which is represented by client and object parameters. Important parameters are the kind of object (pipe, plate or bend), the nominal wall thickness, the lift off and the type of cladding used. Based on this information and the experience of the operator, a suitable probe is selected and a suitable scan is defined. After a reference measurement is performed and the complete survey is done, it can be saved. After the survey is saved it is possible to export the data in a convenient format for analysis and evaluations in other software systems. The program gives tools to inspect, check, evaluate and report the measurement data.

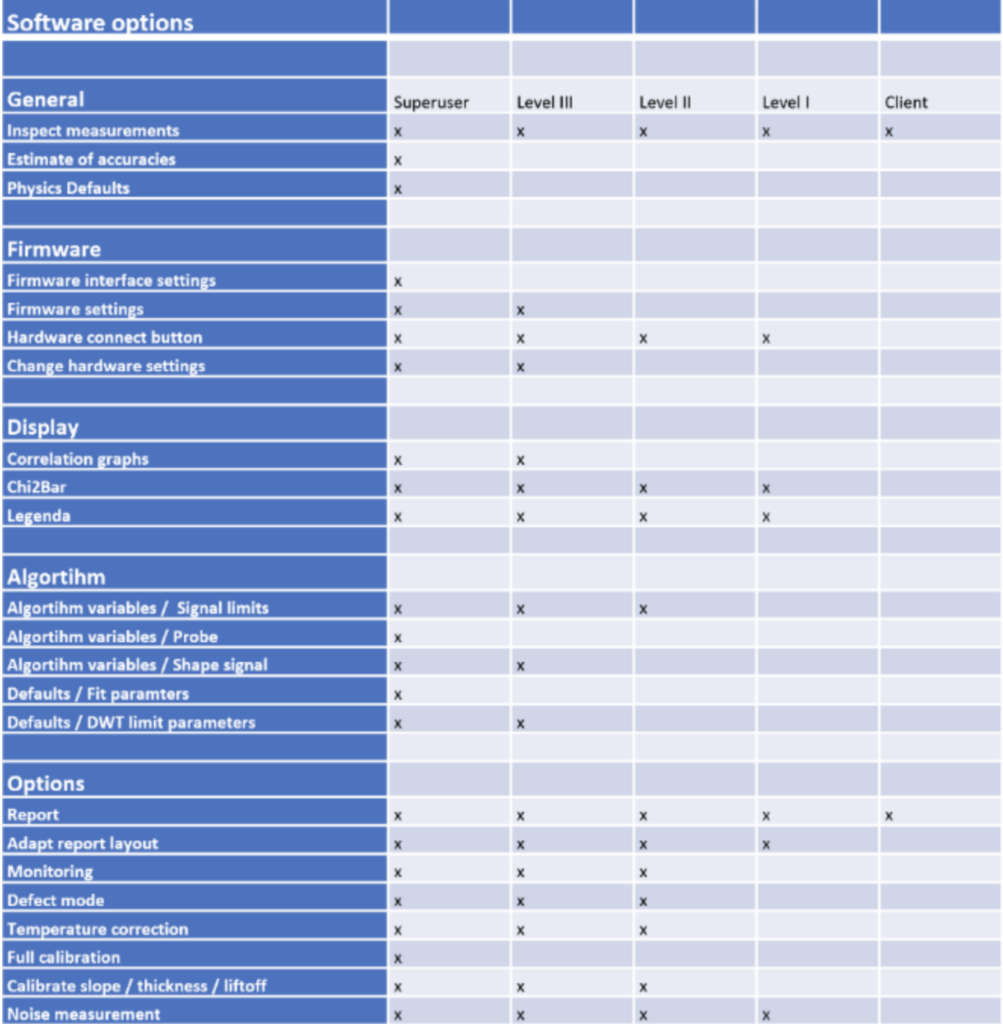

The program can be used in different password protected modes. The simplest mode is ‘Client’, where the measurement results can be accessed and investigated only. The normal mode is ‘Operator Level 1’ mode, which gives all needed functionality to perform a typical NDT survey. The ‘Operator Level 2’ mode enables the adaptation of some of the graphical

features (like colours, fonts and sizes) and the creation of adapted probe settings. Further it enables the possibilities to perform ‘Monitoring measurements’. ‘Operator Level 3’ is for the advanced operators and the ‘Superuser’ mode gives full program control of all algorithm and probe settings. See the following table for further specification of the software belonging to the different modes:

There is a specific user manual for each software user guide.

A very important feature of this software program is the possibility of automatic reporting. It is capable of providing you with an automatic generated document of your choice (word or excel).

The benefits of using this software at a glance

Software benefits:

- Fast data collection

- Direct real-time interpretation and results

- Data digitally stored

- User-friendly operation (touchscreen)

- Advanced PEC signal presentation feature

- Advanced PEC data analysis and evaluation algorithms (footprint minimum WT value, etc.)

- Advanced reporting features (Auto report generation, Graphs, 3D result projection on object model/photo, etc.)

- In-service corrosion monitoring

- Interface language user dependent

- Operator level dependent software and training