Typical Applications of PEC

The typical applications of the PEC measurement methods are listed below and the method of BonPEC applies to as well.

Corrosion Under Insulation (CUI)

The most common insulated objects in a plant consist of pipes and vessels. It is important to monitor and control the integrity of these parts to assure continuity and avoid un-expected breakdowns.

BonPEC can be successfully applied for the detection of CUI which is one of the most common degradation mechanism for insulated pipes and vessels in plants.

Corrosion under fireproofing (CUF)

Generally when a Spherical Tank goes out of service for maintenance, most NDT and inspection activities are focused on the Pressure Vessel body. The support legs are also important components and they contribute to the global integrity of the Spherical Tank. Examination of the legs is mainly a visual examination of the outside fireproofing.

BonPEC allows for a good evaluation of the integrity of Spherical Tank Support Legs through its fireproofing. When the support legs are not considered or not good examined, there may be serious consequences for the integrity of the structure that may collapse during a water test prior to its going back to service (see the image). Water is generally heavier than the liquefied gas product stored in this Pressure Vessels types.

Flow Accelerated Corrosion (FAC)

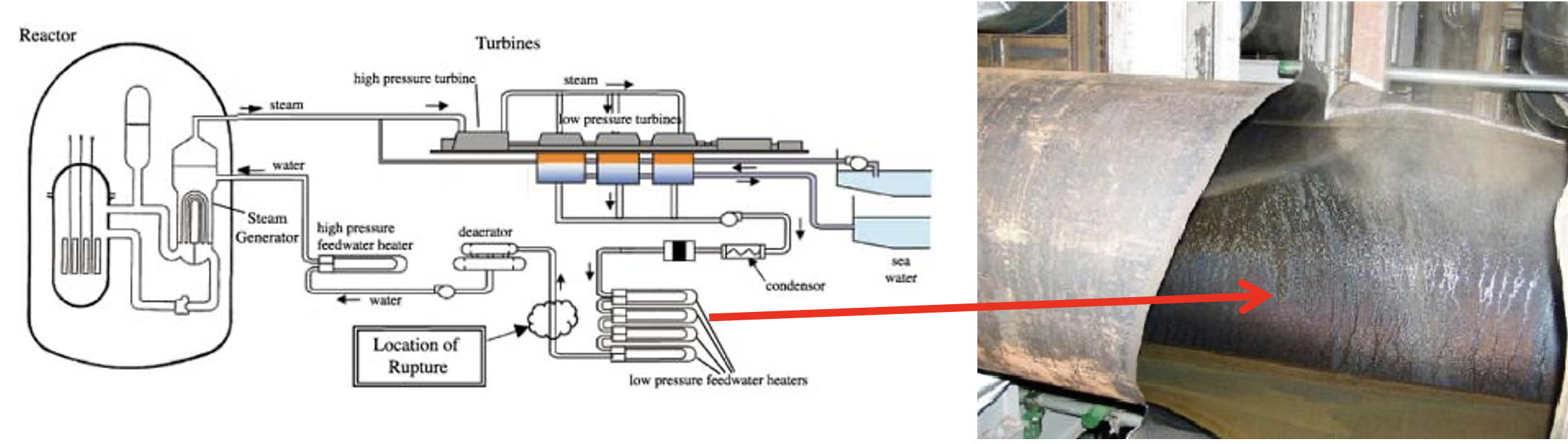

Flow Accelerated Corrosion (FAC), also known as flow-assisted corrosion, is a degradation mechanism in which a normally protective oxide layer on a metal surface dissolves in a fast flowing fluid. The underlying metal corrodes to re-create the oxide, and thus the metal loss continues until eventually the remaining wall thickness is insufficient to contain the internal pressure and rupture occurs.

Many pipe failures caused by FAC have been reported in power plant piping systems. Under certain water chemistry, fluid velocity, and operating conditions, FAC can cause internal wall thinning of condensate and feed water piping, heater drip and drain lines, and other carbon steel piping. In some cases, this thinning has led to catastrophic failures and fatalities.

This image shows the Mihama accident damage in 2004. FAC typically occurs in the temperature range of approximately 80°C to 300°C and is commonly found in economizer tubing, low pressure evaporator tubing, drum internals and feed water systems. In addition, the propensity for forming FAC damage is greater in areas of high turbulence, mostly in elbows and its damage may extend to the straight pipe section up for approximately a length of 1 pipe diameter upstream and 2 pipe diameters downstream.

In-service corrosion monitoring

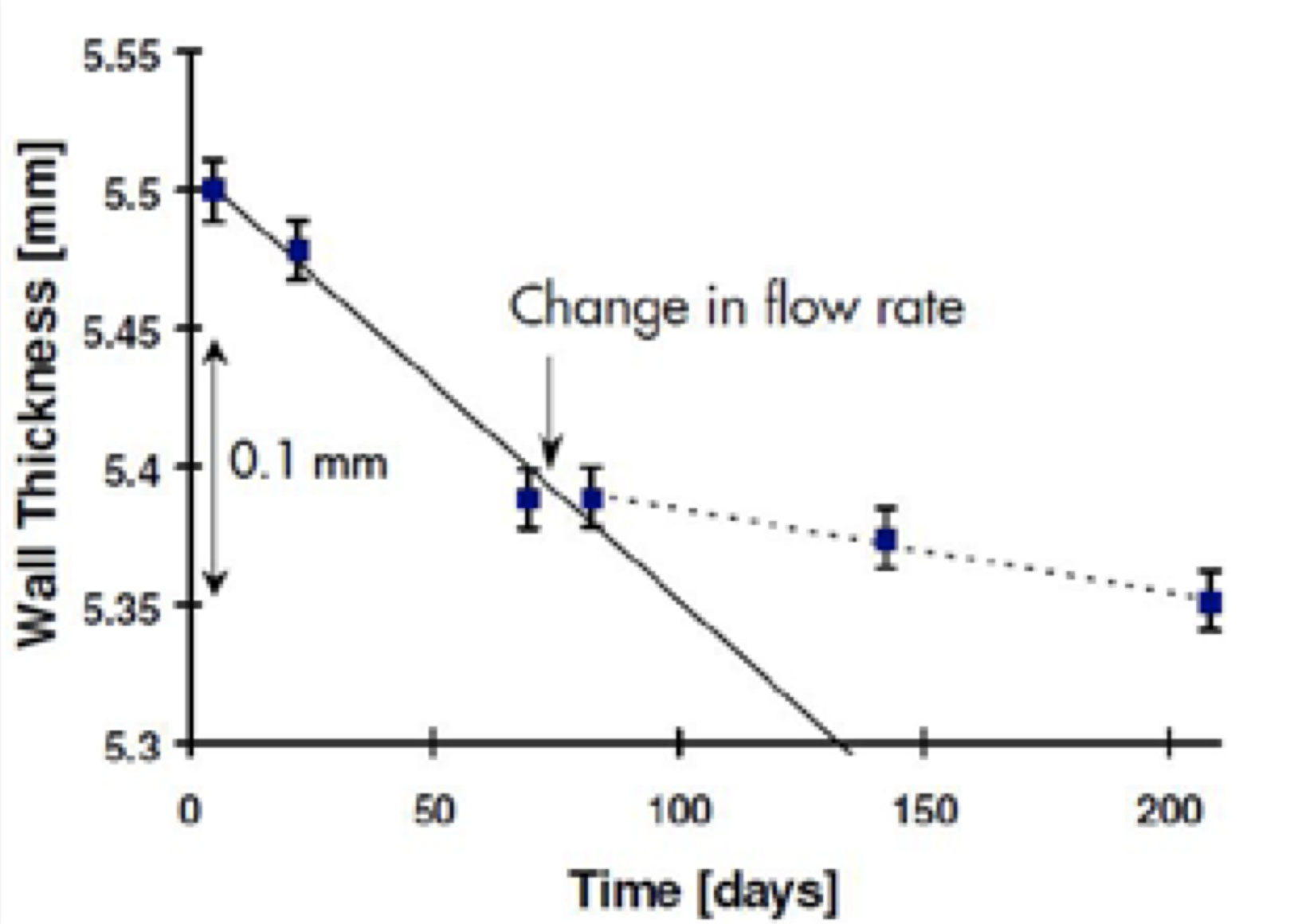

PEC measurements are generally highly repeatable. This makes it well suited for corrosion monitoring purposes. Corrosion rates can be deduced from wall thickness measurements over a time interval at fixed locations.

For example, PEC corrosion monitoring was recently installed to the test on a refinery furnace outlet operating at 420°C. The asset owner discovered that an inappropriate material had been used in the construction of the elbows of the outlet, which led to unacceptable high corrosion rates. Measurements at two-week intervals confirmed the expected corrosion rates. The high reproducibility of PEC readings at one spot allowed the asset owner to quickly and accurately monitor the degradation of the plant over time.

Heavily corroded equipment

Another application of PEC is in-service assessment of heavily corroded pipes and vessels. Often, safety considerations do not allow the corrosion products to be removed on stream. In this case, PEC has the crucial advantage that it can be applied without disturbing or even touching the corrosion products.

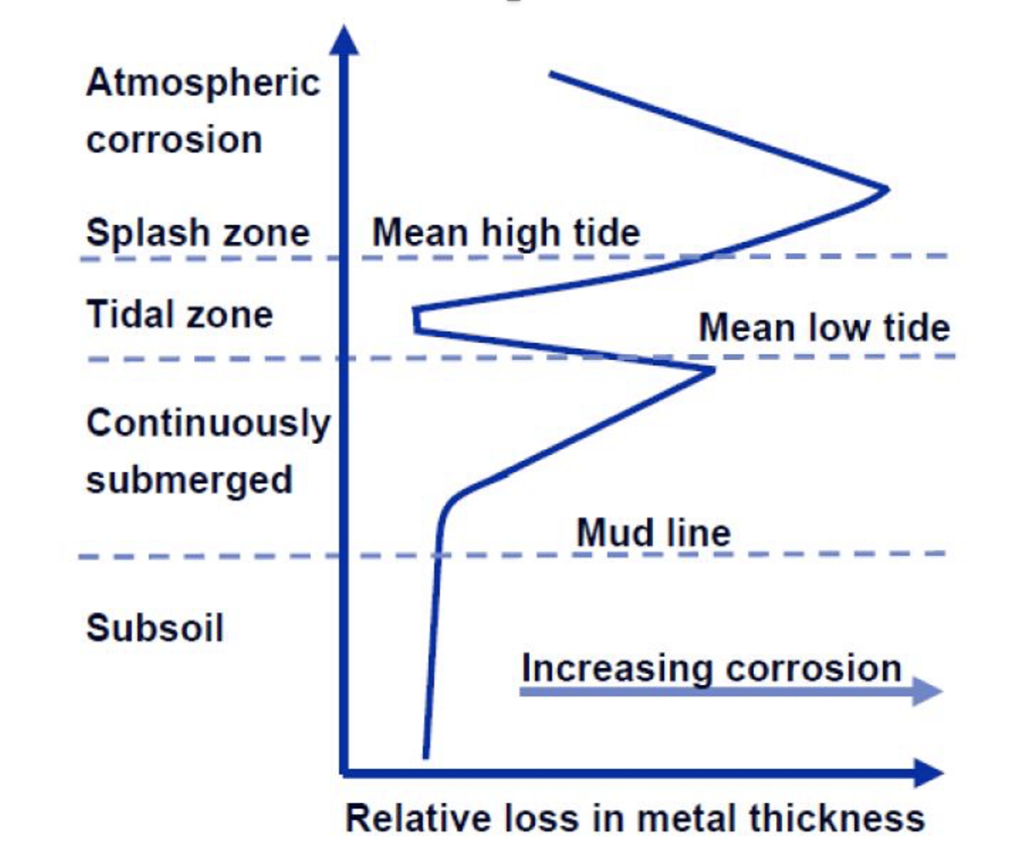

Offshore risers, caissons and structures

PEC is the cost effective solution to examine the Splash Zone area of raisers, caissons and offshore structures. The Splash Zone is the most aggressive corrosion area, see the graph below and the location in the image at the right.

PEC can easily measure through the riser coating and through the Monel protective metal layer detecting corrosion in the carbon steel section and through the marine growth layer.

Operation is generally performed with rope access and divers. To increase safety and to reduce risks, PEC measurements can be deployed remotely mounted on a riser tool. Different riser tools have been developed with diameters from 15” up to 50” in Australia and in Europe.

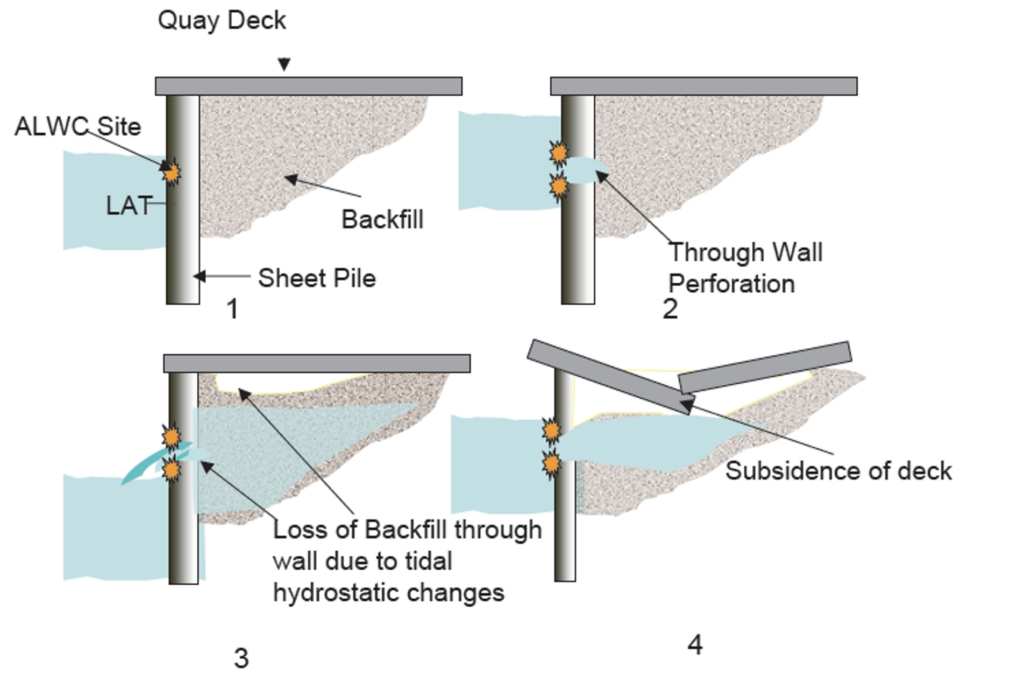

Steel Sheet Piling

Steel Sheet piling are commonly present in harbours, channels, sluices and dams to protect this facilities. They are particularly common in The Netherlands where approx. 40% of the territory is below sea level and where waterways and port areas have a very high economically value.

Corrosion and degradation of Steel Sheet Piling is a continuous deterioration process that may lead to serious safety, economical and legal consequences for Port and Waterways Authorities. If not monitored and controlled during their service life, serious degradation can be expected after only 10 years of operation for example due to accelerated degradation processes such as Accelerated Low Water Corrosion (ALWC), a form of corrosion caused by microbial growth that can occur on inshore, tidal, marine, steel piled structures. Its consequences can be expensive, often requiring costly remedial works and unplanned facility downtime. Corrosion rates in excess of 3 mm/year have been observed and if left untreated can results in the integrity of the facility being seriously compromised.

Corrosion degradation of these structures may be also as consequence of high-low tide, fresh and saltwater mixing and it may be more aggressive in the Splash Zone due to the higher concentration of Oxygen. Damages can also be mechanical due to ship movements and impacts.

Visual examination and UT verification are traditionally used for the examination and inspection of Steel Sheet Pilings. PEC is a cost saving alternative solution for screening and monitoring these structures:

- PEC screening supports the prioritisation of the maintenance actions and, the proper and effective allocation of the available maintenance budget and resources where they are exactly needed.

- PEC monitoring will gain long-term financial savings in maintenance versus the possibility of a complete replacement or reconstruction, which is very significant.