Probes

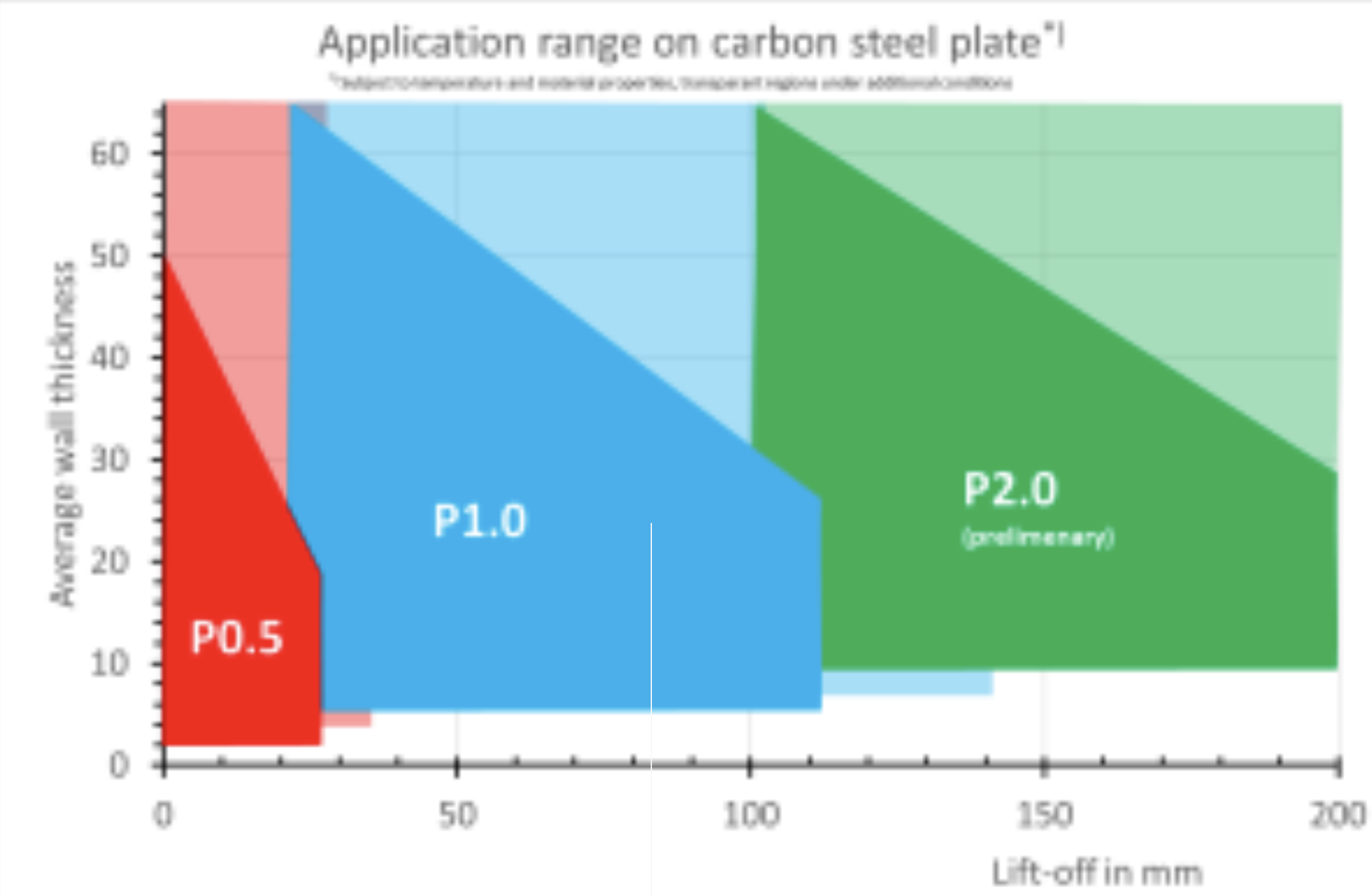

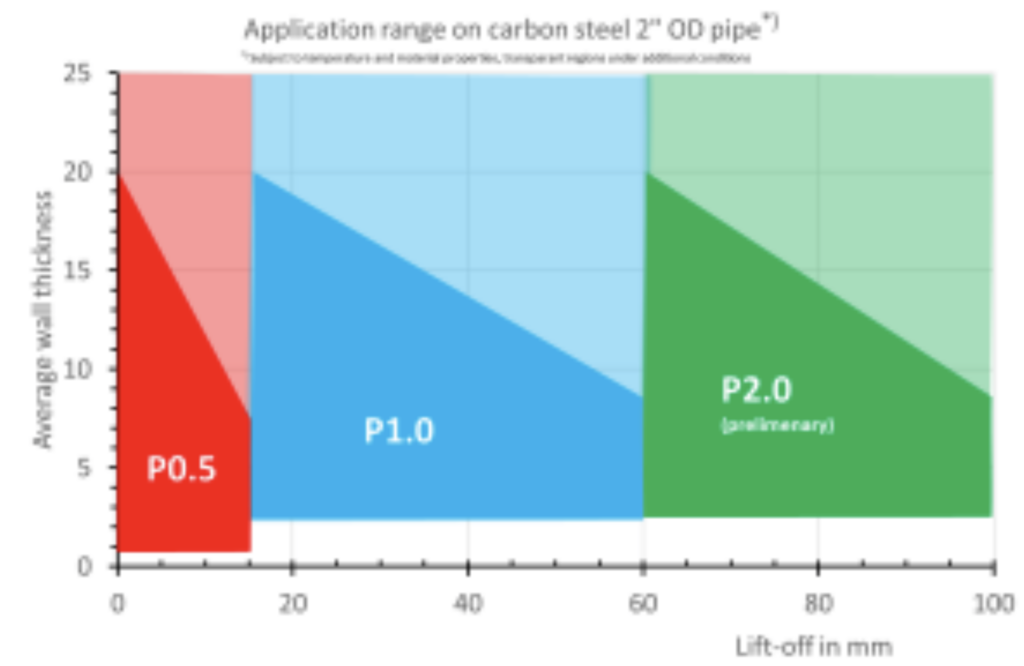

Depending on the lift-off and the average wall thickness of the object to investigate, a choice must be made about which probe to use to optimize the reliability of the inspection. For a large lift-off a large probe is needed. Two probes are directly available P0.5 and P1.0, another probe for even larger lift off is under development (P2.0). The applicable range of each probe depends on the material properties and the geometry of the component to be inspected. The most important parameter are the lift-off and the average wall thickness of the component to be examined.

The graph below shows the selection diagram for a carbon steel flat plate:

The graph below shows the selection diagram for a 2″ carbon steel pipe:

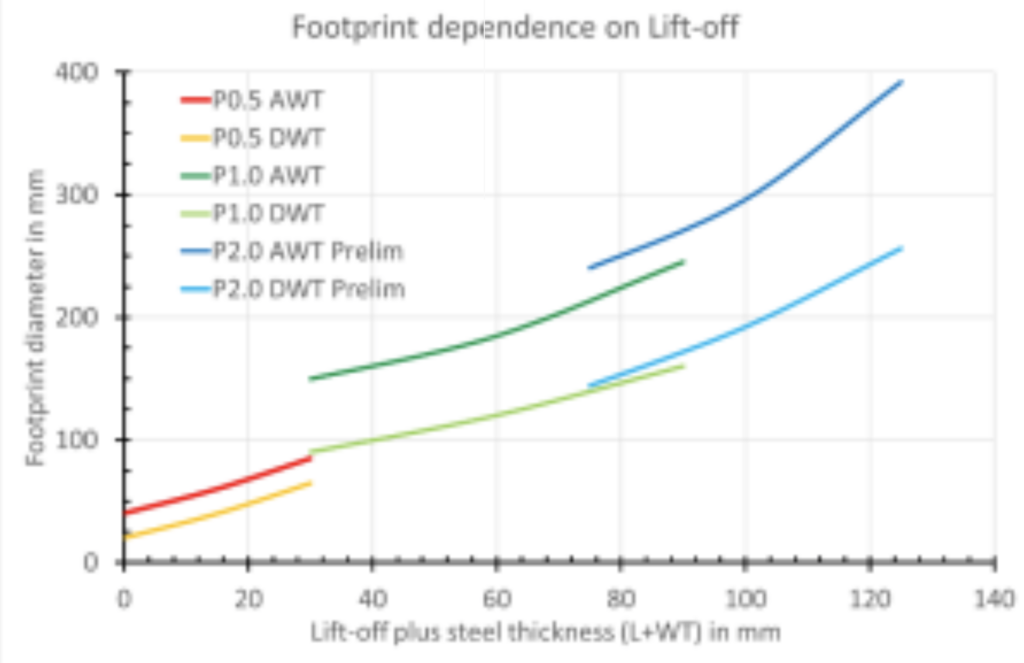

The corresponding footprints for each probe are shown in the picture below:

The ‘AWT’ represents the Average Wall Thickness footprint and the ‘DWT’ represents the footprint for the Defect Wall Thickness algorithm.

BonPEC probes are designed to minimize false readings, hence they are insensitive to metal objects near the probe, except for the object that is right below it and need to be examined. Because of this focusing the probes are (within boundaries) insensitive to the lift-off, angle mismatch or thickness of the sheeting. These are all important parameter for measurements in the fields reducing false calls and increasing effectiveness of data interpretation as the acquired signal is robust against these changes.